- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

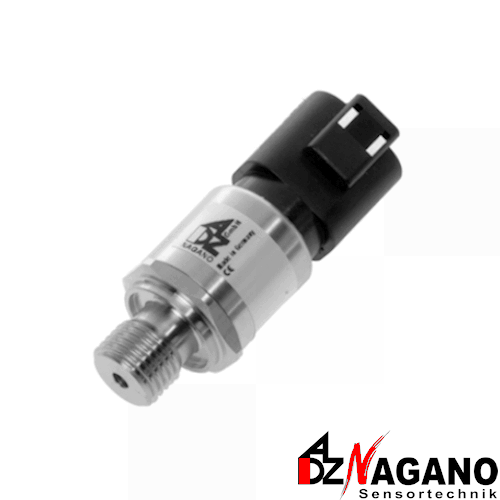

Pressure Transmitter in Mobile Hydraulics

The pressure transducers of this series are specially designed and developed for Mobile applications and Off-Road Vehicles. Development of EMI and environmental robustness are made for these transducers. These transducers are able to be fitted with a “load dump” module. This module provides protection to load dump pulse according to ISO 7637.

In addition, snubbers can be attached to these transducers. These snubbers are intended to reduce pressure spikes in hydraulic applications. Snubbers are available with opening diameters of 0.6mm (0.0236 inch) or 0.3mm (0.0118 inch). The pressure port and the sensing element are made of stainless steel and fully electrobeam welded in a special process.

- Fully welded construction

- High chemical/media compatibility by the use of stainless steel

- High rate of pressure cycle withstand

Due to its stainless steel membrane and to its semiconductor thin-film technology, the transducer has excellent properties regarding its long-term stability, medium compatibility and pressure peaks that suggest its advantageous use in most industrial applications. Also its robustness, even in very rugged ambient conditions in the field of mobile hydraulics, is guaranteed by its welded stainless steel housing. The EMC properties of this series permit its application also in sophisticated environments. Its ratiometric model has been successfully tested up to 300V/m.

Features:

- Measuring ranges -1…0 bar & 0…5000 bar

- Output signals 4-20 mA; 1-5 V; 0-10 V; 0.5-4.5 V ratiometric

- Temperature range of media up to 150°C

- Shock and vibration resistance > 1000 g shock, > 30 g vibration

- Protection class IP67 (special version up to IP69K)

- Compact and rugged model in stainless steel

- High flexibility for options thanks to modular design

- Highly reliable

Specifications

| Pressure range: | up to 5000 bar |

| Max over pressure: | 2 times nominal pressure |

| Min burst pressure: | 3 times nominal pressure |

| Output signals: | 4-20 mA, 0-10 V, 0.5-4.5 V ratiometric CANopen (SMC), J1939 |

| Response time [10-90%]: | ≤1 ms |

| Accuracy: | 0.5% F.S. |

| Working temperature range (media): | -40 … 125°C |

| Working temperature range (ambient): | -40 … 105°C |

| Material of parts in contact with media: | stainless steel 1.4301 / 1.4305 / 1.4542 |

| Material of housing: | stainless steel 1.4301 |

| Shock resistance (according IEC 60068): | 1000g |

| IP class (according IEC 60529): | up to IP69K (depending on electrical connection & mating) |

| Weight: | 80 – 120 g |

| Minimum pressure cycles: | 1*107 |

Applications

- Automotive industry

- Diesel and natural gas engines

- Braking systems

- Hydraulics

- Pneumatics

- Industrial Equipment and Automation technology