- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

Flow Meters

Flowmeters are devices that measure the amount of liquid, gas or vapour that passes through them. Some flowmeters measure flow as the amount of fluid passing through the flowmeter during a time period (such as 100 litres per minute). Other flowmeters measure the totalized amount of fluid that has passed through the flowmeter (such as 100 litres).

Flowmeters consist of a primary device, transducer and transmitter. The transducer senses the fluid that passes through the primary device. The transmitter produces a usable flow signal from the raw transducer signal. These components are often combined, so the actual flowmeter may be one or more physical devices.

Flow measurement can be described by

Q = A · v, which means that the volume of fluid passing through a flowmeter is equal to the cross-sectional area of the pipe (A) times the average velocity of the fluid (v); and

W = r · Q, which means that the mass flow of fluid passing through a flowmeter (A) is equal to the fluid density (r) times the volume of the fluid (Q).

Volumetric flowmeters directly measure the volume of fluid (Q) passing through the flowmeter. The only flowmeter technology that measures volume directly is the positive displacement flowmeter.

Velocity flowmeters utilize techniques that measure the velocity (v) of the flowing stream to determine the volumetric flow. Examples of flowmeter technologies that measure velocity include magnetic, turbine, ultrasonic, and vortex shedding and fluidic flowmeters.

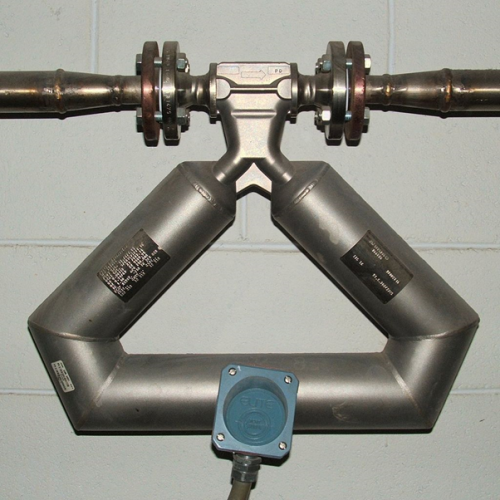

Mass flowmeters utilize techniques that measure the mass flow (W) of the flowing stream. Examples of flowmeter technologies that measure mass flow include Coriolis mass and thermal flowmeters.

Inferential flowmeters do not measure volume, velocity or mass, but rather measure flow by inferring its value from other measured parameters. Examples of flowmeter technologies that measure inferentially include differential pressure, target and variable area flowmeters.