- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

DB-Rail section monitoring with ASC sensors during running operation

The condition of the rail network has to be inspected on a regular basis. For several years, Deutsche Bahn AG have also been using regular trains for monitoring infrastructure as part of their DB 4.0 digitalisation strategy. High-precision sensors from ASC GmbH in Pfaffenhofen, Germany are used to scan the track bed with millimetre precision here.

Three to four trains, including second-generation ICEs and ICs, are used for “continuous track condition monitoring.” The thought process behind this is that, since long-distance trains are already traversing the rail network day in and day out, why not have them collect data at the same time. DB Netz AG, who are responsible for the rail infrastructure, commissioned intragroup company DB Systemtechnik GmbH for the task. Defects in longitudinal level are the main type recorded, making up round 75 per cent of all so-called track geometry defects. Measurement runs help Deutsche Bahn identify deviations in the track geometry before costly damage occurs. They supplement regular inspection with track measurement trains at longer intervals, with high-speed rail sections usually being examined every three to four months and regional train sections once a year.

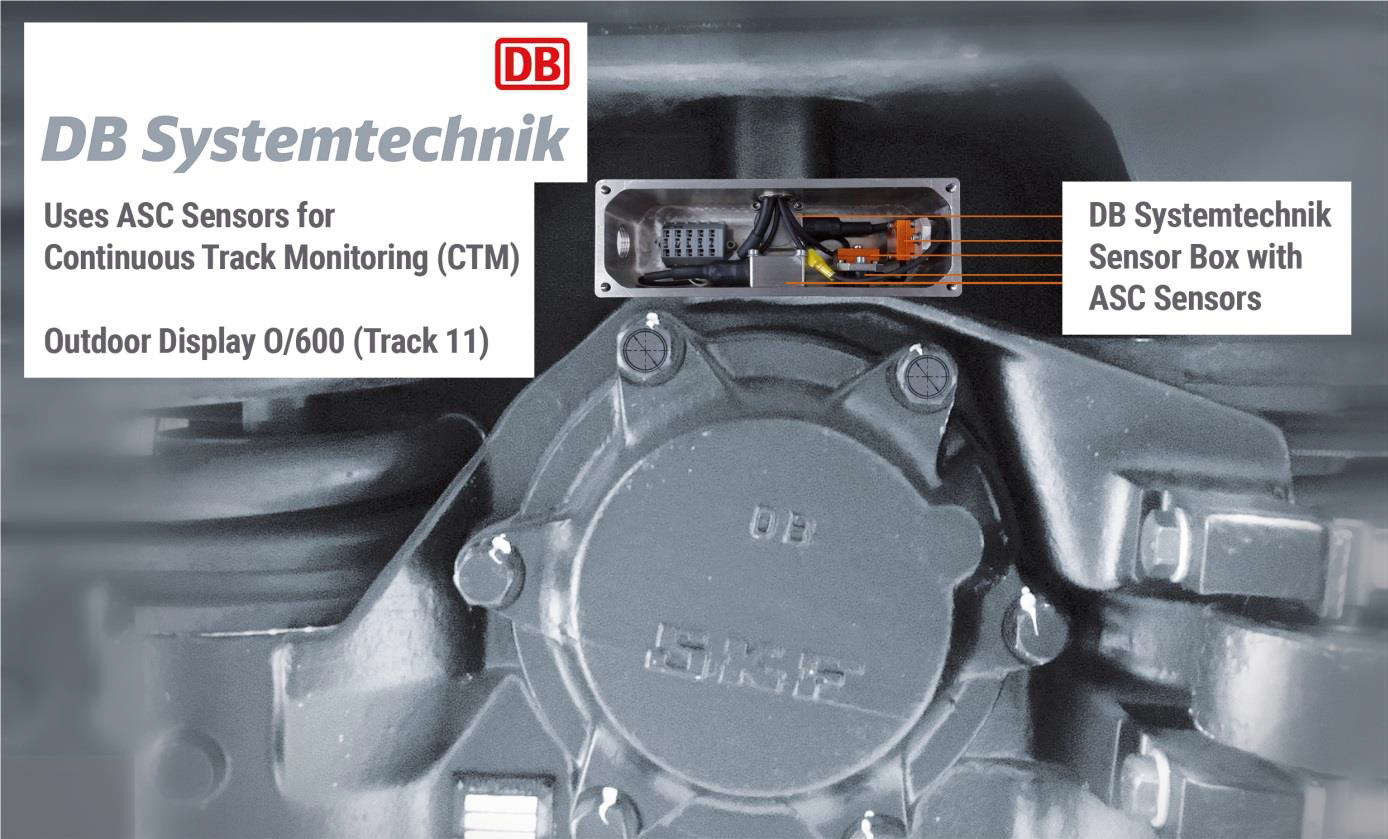

Measurement data are often just a few hours old“Our goal is to monitor a large rail network with just a few vehicles,” said Dr.-Ing. Klaus Ulrich Wolter, “continuous track section monitoring” expert at DB Systemtechnik GmbH in Munich who was instrumental in setting up the measurement system from the beginning. The main components of the system are sensors located in the bogie and the interior of the railcar body of a train. A data recording system, a positioning system and a system for data transmission are also used. The positioning system continuously saves the current location of the train so that the measurement values can be allocated to a specific point of the rail section. The data transmission unit, on the other hand, sends all data to DB Systemtechnik in Munich-Freimann in real time. DB Systemtechnik evaluate the data once a week and make it available to the persons responsible for the rail system at the respective point. As evaluation largely occurs automatically, reports may even include data which are just a few hours old at the time they’re sent.

Several thousand kilometres of rail network are monitoredAt present, around 2,500 km of rail are monitored for their condition on a weekly basis. Long-distance trains with special sensors don't just travel the oft-traversed north-south route between Bremen/Hamburg and Munich, but cover the sections between Berlin & Cologne and Halle/Leipzig & Bremen as well. “Some rail sections are only traversed by trains with measurement technology every two weeks, while others are covered up to two times a day,” reported Dr. Wolter. “On average, though, rail sections are traveled by trains with measurement technology four times a week.”

The quality of the data obtained in this way heavily depends on the sensors used. This is why DB Systemtechnik chose to use acceleration sensors from ASC GmbH in Pfaffenhofen, Upper Bavaria. “Our colleagues in Minden have been using them for a while and are very satisfied with them,” said monitoring specialist Wolter in justifying their choice. “The technical specifications are perfect for the job, and we get outstanding support.”

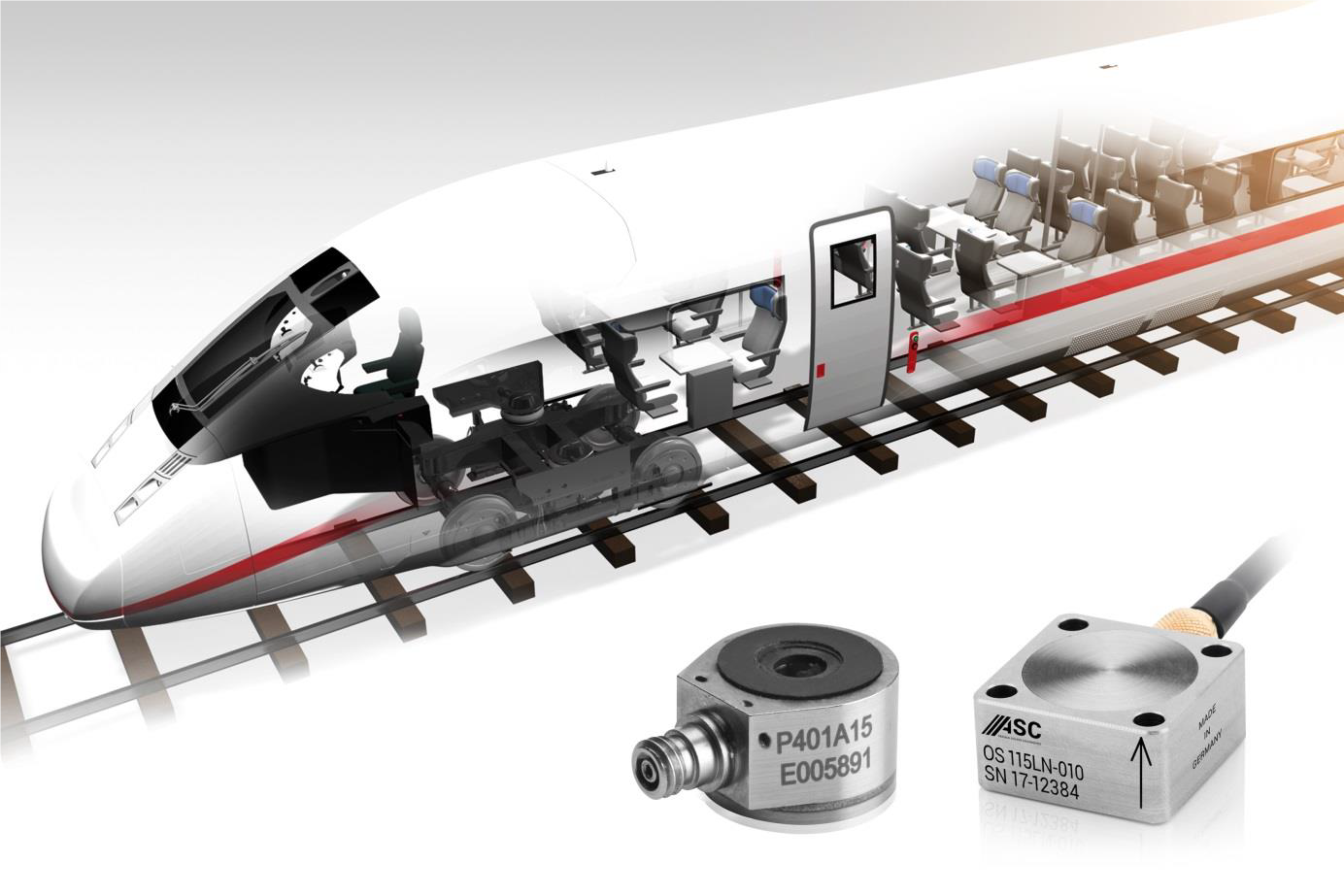

In addition to the ASC OS-115LN 050 and ASC OS-115LN 002 uniaxial accelerometers, the ASC P401A15 piezoelectric model is also mounted on the long-distance trains. The latter is a high-frequency IEPE sensor (Integrated Electronics Piezo Electric), characterised by its extreme ruggedness & impact resistance and hermetic seal. These sensors feature a broad frequency range from 0.5 Hz to 15 kHz and a measurement range of ±50, ±100 and ±500 g. Their high impact resistance up to 5,000 Gpk is a major advantage for use in rail traffic with its high shock loads. Another argument for the ASC P401A15 is its broad temperature range of –55 to +150 °C, as temperatures at the measurement points of the trains can vary from –30 to +70 °C.

Measurements prevent track blockages and delaysThe ASC sensors measure both the vertical acceleration at the wheel set bearings and the acceleration on the interior of the railcar bodies. In this way, they primarily monitor the longitudinal level of the superstructure composed of rails, sleepers and ballast. The focus here is measurement of the longitudinal level, as it changes the fastest and deviations in this area have the largest effect on operating quality. If there are defects present in the geometry here, maintenance measures must be taken or speed-restricted sections established immediately. This would lead to delays in rail traffic and thus a great deal of inconvenience as a result.

The measurement ranges of the OS-115LN 002 and OS-115LN 050 accelerometers from ASC used by DB are 2 g and 50 g, respectively. The signal-to-noise ratio of the sensors, which lies between 7 and 400 μg/√Hz depending on the measurement range, is also very good. For continuous track condition monitoring by Deutsche Bahn, the high sensitivity and impact resistance of the ASC sensors are of primary importance. The small size of the measurement systems was also decisive, as the installation space in the so-called sensor boxes on the trains is limited.

The sensors from ASC measure the vertical acceleration at the wheel set bearings and on the interior of the railcar bodies, thus monitoring the longitudinal level of the track superstructure.

In addition to capacitive and piezoelectric acceleration sensors, DB Systemtechnik also use gyroscopes of type ASC 271. These sensors are based on MEMS technology (Micro-Electro-Mechanical System) and are specially suitable for measuring track geometry defects in bogies. One special feature of the sensors is their outstanding bias instability of 9 °/hr, and they are also characterised by a very low noise density of 0.02 °/s/√Hz and a low angle random walk (0.2 °/√Hz).

The ASC 271 gyroscopes monitors the rail section condition in bogies.

It wasn’t just the high precision and ruggedness of the sensors that convinced Dr. Wolter – he also appreciates ASC’s high flexibility: “A sensor was specially adapted to our needs so that the cable is now permanently connected to the unit.” Strong customer orientation is a trademark of the sensor specialists, who produce a majority of their products custom tailored for special applications. As production is carried out at their headquarters in Germany, the quality standards applied are also very high.

The sensor box of DB Systemtechnik is outfitted with ASC sensors. It can be seen at the ASC stand in Hall 6.2, Stand 219, and on the open grounds at O/600 on track 11. Image: DB Systemtechnik

Since the introduction of continuous track condition monitoring, the mobile measurement technology has already been used over more than 6,000,000 kilometres. Based on the data obtained, measures were initiated which considerably improved the quality of the superstructure comprised of the rails, sleepers and ballast. This made it possible to reduce the number of speed-restricted sections and track blockages by an average 95 per cent. A further indicator of the success of monitoring is the great interest in measurement data seen by persons responsible for rail systems. As requested by them, more and more sections of rail will be included for monitoring, bit by bit. At present, continuous track condition monitoring is still limited to long-distance sections, but Dr. Wolter is already considering expansion: “The technology is definitely also of interest for the extensive rail network of regional trains.”