- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

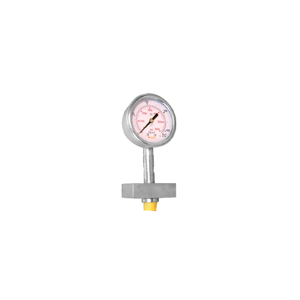

Intrinsically Safe Pressure Transmitter

The SMX2 can be configured in both zone 0 and zone 1 and meets the requirements of Directive IBExU 10 Atex 1014. Appropriate protective circuits guarantee inverse-polarity protection, overvoltage resistance and limitation of capacity loss in the event of any failure. Its widely ranging industrial applications are guaranteed by its high precision and robust and compact design. A wide range of pressure transducers is on offer with the possibility of combining various mechanical and electrical connections.

The SMX2 can be configured in both zone 0 and zone 1 and meets the requirements of Directive IBExU 10 Atex 1014. Appropriate protective circuits guarantee inverse-polarity protection, overvoltage resistance and limitation of capacity loss in the event of any failure. Its widely ranging industrial applications are guaranteed by its high precision and robust and compact design. A wide range of pressure transducers is on offer with the possibility of combining various mechanical and electrical connections.

The SMX2 in field housing has been designed for application in rugged environments. Thanks to its stainless-steel thin-film measuring cell, this pressure transducer features excellent properties, it is extremely robust, fully welded and without any hydraulic transmission media. The measuring range can be freely positioned at a ratio of 4:1 in the upper end range. There is also the possibility to freely select the response time. Both parameters can be managed with the help of a service box, including software. Further advantages of this model consist in the transmitter being able to be adjusted or calibrated even without having to separate it from the measuring loop. Tests can be performed within the system by means of a loop generator (pressure simulator) inside the transmitter.

Zone 0, an area where an explosive atmosphere of a mix of air and combustible gases, vapours or sprays is permanently, over long periods or frequently prevails.

Zone 1, an area where an explosive atmosphere of a mix of combustible materials in the form of gas, vapour or spray with air occurs occasionally in normal operation.

Safety Note: When fitting, commissioning and operating this pressure transmitter, please observe relevant national safety regulations by all means

Technical Data

| Pressure range: | 0 to 2000 bar / 14,500 to 29,000 PSI |

| Output signals: | 4-20 mA |

| Response time [10-90%]: | ≥ 4 (digital) ≥ 1 (analog) |

| Accuracy: | % of the range ≤ 1.00%, Option ≤ 0.50 |

| Working temperature range (media): | -40 … 100°C / -40 … 212°F |

| Working temperature range (ambient): | -40 … 85°C / -40 … 185°F |

| Material of parts in contact with media: | stainless steel |

| Material of housing: | stainless steel |

| Shock resistance (according IEC 68-2-32): | 1000g |

| IP class (according IEC 60529): | up to IP6K9K (depending on electrical connection & mating) |

| Weight: | 120 – 150 g |

| Minimum pressure cycles: | 1*106 |