- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

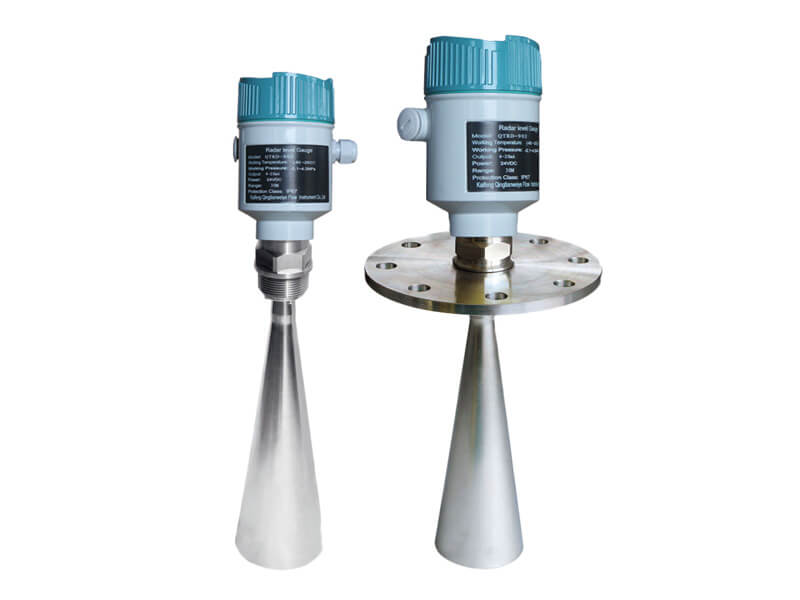

Radar Level Sensor

In radar level measurement, microwaves are transmitted by the antenna system of the radar sensor to the measured product, reflected by the product surface, and received back by the antenna system. The time from emission to reception of the signals is proportional to the level in the vessel. Non-contact level measurement with radar is characterised by a particularly high measurement accuracy. The measurement is affected neither by fluctuating product properties nor by changing process conditions such as temperature, pressure or intense dust generation.

Radar level transmitter antenna transmits narrow microwave pulses downward. Microwave exposure to the medium surface is reflected back to the antenna. The antenna system sends that signal to the electronic circuit and it gets automatically converted into level signals (because the microwave propagation speed is very fast as the time for electromagnetic wave to reach the target and to get reflected to the receiver is almost instantaneous).

This series of radar level meter has 26G high frequency radar sensor and the maximum measurement range can reach up to 70 meters. Antenna is optimised for further processing, the new fast microprocessors have higher speed and signal analysis can be done more efficiently. This kind of instrumentation can be used for reactors, solid silos and very complex measurement environment.

Features:

- Small antenna size, easy to install, Non-contact radar, no wear and no pollution

- Almost no corrosion, no bubble effect, not affected by water vapour in the atmosphere, temperature and pressure changes

- Unaffected by sludge & biomass, dust, foam, oil, grease & other coatings, uneven surfaces, turbulence, pressure and vacuum

- Due to shorter wavelength, the reflection of solid surface inclination is better

- Simple mounting and push-button calibration

Specifications

| Medium | Suitable for all kinds of corrosive liquid |

| Explosion-proof Grade | Exia IIC T6 Ga |

| Measuring Range | 70 meters |

| Frequency | 26 GHz |

| Temperature: | -40℃ ~ 120℃ |

| Measurement Precision | ±5 mm |

| Process Pressure | -0.1 ~ 0.3 MPa |

| The signal Output | (4 ~ 20) mA/HART (Two wire/Four ) RS485/Modbus |

| The Scene Display | Four digital LCD |

| Shell | Aluminium |

| Connection | Flange(optional)/Thread |

| Protection Grade | IP67 |

Applications

Radar sensors have wide range of applications – be it in simple storage tanks, in corrosive or aggressive media or high accuracy tank gauging applications.